e-Transformers

Background

The primary

driver of rising CO₂ levels in the atmosphere is the burning of fossil

fuels. To combat this, we aim to transition towards electrification, which has

the potential to significantly reduce CO₂ emissions. Electricity can be

generated from renewable sources such as solar cells or wind turbines, enabling

a cleaner and more sustainable energy system.

State of the art

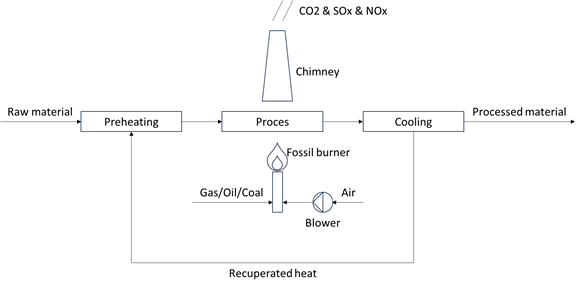

Fossil

fuels are widely used for heating in various industrial processes, including

the melting of metals and ceramic materials. In the chemical industry, heat is

often generated through combustion, which contributes heavily to CO₂

emissions.

Example cement production

Today,

nearly all cement is produced using a high-temperature

burning process that relies on fossil fuels such as coal, oil, or gas. This

method is energy-intensive and one of the largest contributors to industrial

carbon emissions worldwide beside from pollution from SOx

and NOx.

Traditional electrical

heating methods

While electrical

heating methods have been explored, several challenges hinder their widespread

adoption in high-temperature industrial applications:

Material Constraints

- Cables made from materials

like aluminum or copper cannot withstand the extreme temperatures in

heating zones, where they would melt.

- Heating elements are made from

materials such as FeCrAl

(iron-chromium-aluminum alloys), which are capable of withstanding high

temperatures but cannot be used as cables extending to the power supply

due to their high electrical resistivity and brittle mechanical

properties.

Connection Issues

- Achieving robust mechanical

and electrical connections to heating elements is critical.

- Oxides, which form on metal

surfaces, have low electrical conductivity and impair connections over

time.

- Different metals used in the

connection points have varying thermal expansion coefficients. These

differences lead to mechanical instability, causing connections to loosen

during thermal cycling in the system's operation. If welded, they tend to

develop cracks, which can increase electrical resistivity or even cause

the heating element to disconnect entirely.

- The current feedthroughs from

the cables to the heating elements can be completely

eliminated, allowing for the creation of an efficient pressure

chamber around the heating elements.

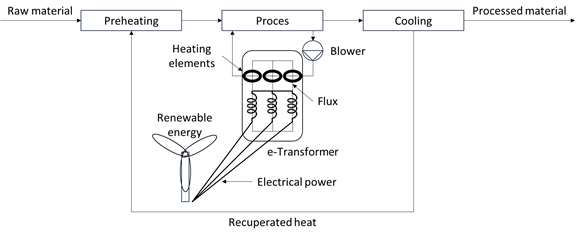

Description of

e-Transformers

The

e-Transformers concept introduces a novel approach to high-temperature

electrical heating. By addressing the limitations of traditional methods, this

solution ensures reliable performance under extreme conditions.

Key features include:

- Heating elements capable of

maintaining integrity at high temperatures.

- The heating elements are energized

by magnetic induction technology, directly supplied from a grid connected

transformer. This design eliminates the need for terminals, cables, or

connections, consisting solely of the heating element material.

- A transformer is also required

in traditional electrical heating systems, as the voltage needed for the

heating elements is significantly lower than the voltage supplied by power

lines. This requirement adds a competitive advantage to the overall cost

of the heating system, because the transformer is needed anyway for all high power installations.

- A modular system that can be

adapted to different industrial processes. I.e. different levels of

temperature, dust and fluids.

- It is possible to loop back the

fluid from the process to the e-Transformer, at a very high temperature

(i.e. more than 600°C), which increases the process efficiency

considerably, because the temperature only needs to be increased by i.e.

300°C.

Possibilities and

advantages

Reduced

CO₂ Emissions: Transitioning from fossil-fuel-based systems to electrical

heating directly reduces carbon footprints.

Integration

with Renewable Energy: The system is compatible with renewable electricity

sources, enabling sustainable industrial processes.

Prototype

A 1-phased 3kW

prototype has been developed to validate the concept. It is currently being build to verify the simulation software, which makes it

possible to upscale the machine to a much higher power level. The next

prototype is expected to be around 1MW and has a 3-phased connection to the

power grid.

The

e-Transformers prototype represents a step towards electrifying industrial

heating processes, offering a cleaner and more sustainable alternative to

fossil fuels.

Solving

hard-to-abate Industries with electrical heating

e-Transformers

|

Replacing fossil burners with

electrical heating at very high temperature using a robust electrical heater |

|

|

Reliable: No terminals/cables required for

hot connection Inductive heating of Simple

elements |

Advantages: Use necessary transformer

directly Local use and production of

electricity |

|

Present |

|

|

|

|

|

|

|

|

Future options |

|

|

|

|

Executed till now: 1. Prototype 2. 3 kW in, collaboration w. Aalborg

University, Denmark |

Future short

term prospect: Partner for industrial application

to substitute part of fossil fuel as a simple low risk add on to existing

operation Operate 1 MW e-Transformer to

substitute fuel when operation is beneficial. |

|

|

|

Mogens Føns M. Sc. Mech. Eng. +45 40845804 |

|

Flemming Buus Bendixen M. Sc. E. E., Ph.D. +45 61631717 |